One third of the world's energy consumption is caused by friction and wear, lubrication technology is an effective means of energy conservation, the exploration of environment-friendly lubrication materials is an important research direction. The Molybdenum disulfide has a lamellar crystal structure (with weak Johannes Diderik van der Waals force between layers, strong covalent bond and easy sliding along the Tangential Direction) , which is a necessary choice for lubrication under harsh working conditions (high temperature, high load, extreme pressure, etc.) , however, there are some problems such as dispersed molybdenum resources, pollution of heavy metals and easy oxidation failure at high temperature. In recent years, our research group of Professor Dong Jinxiang has made a series of progress in exploring new solid lubricant to replace Molybdenum disulfide. According to the characteristics of crystal structure, layered oxides such as layered sodium silicate and layered zirconium phosphate were studied in the early stage. The-and-layered sodium disilicate materials were prepared by a mild synthesis method —— and a low temperature self-pressure method, respectively, which avoided the problems of high energy consumption and the formation of heterocrystalline glass bodies, layered Sodium disilicate can effectively increase the bearing capacity of lubricating oil and grease (adding 1.0wt%-layered sodium disilicate to liquid paraffin base lubricating oil, the bearing capacity of PB increased from 392n to 470n, adding 5.0wt%-layered sodium disilicate to PAO9 lithium base lubricating grease, the bearing capacity of PB increased from 353n to 1568n) Hong Xu, yajie Wang, Huafeng Li, Lei Liu, Feng Deng, Guoxu Chen, Jinping Li and Jinxiang Dong . That's not true. Chem. . 2009,19,6896 something 6900; Xiaosheng Zhang, Weichao Sun, Huijuan Ma, Hong Xu * and Jinxiang Dong . Ind. . Eng. Chem. . Res. In 2014,53,182 something 188 layered zirconium phosphate was prepared in ionic liquid thermal synthesis system, it is found that the wear resistance of mineral base oil (100sn) can be effectively improved (PB value increases from 470n to 598n and the wear resistance spot diameter decreases from 0.58mm to 0.33mm) , alexandra M. "Z. ". Slawin and Jinxiang Dong * . Inor. Chem. . In 2010,49,8270 something 8275, copper, magnesium and nickel ion-exchange-layered Zirconium Phosphate were obtained by direct hydrothermal synthesis, and the effective control of particle size was realized The results of surface analysis of friction pairs show that zirconium phosphate can form a protective film on the surface, and the effect of different particle sizes on lubrication properties is investigated, the anti-friction and anti-wear properties of the smaller particles under relatively mild load are better.

[Xiaosheng Zhang, Hong Xu, Zhijun Zuo, Zhi Lin, Stanislav Ferdov and Jinxiang Dong*.ACS Appl. Mater. Interfaces. 2013, 5, 7989−7994;Xiaosheng Zhang, Hong Xu* and Jinxiang Dong*.JMEPEG 2018, 27,1927–1935;Xiaosheng Zhang, Hong Xu* and Jinxiang Dong.Journal of Wuhan University of Technology-Mater. Sci. Ed. 2019, 34(1), 47-54;Li Chen, Xiaosheng Zhang, Hong Xu and Jinxiang Dong.Tribol Lett 2016, 64,1. CN201310030217.2, CN201310221283.8]

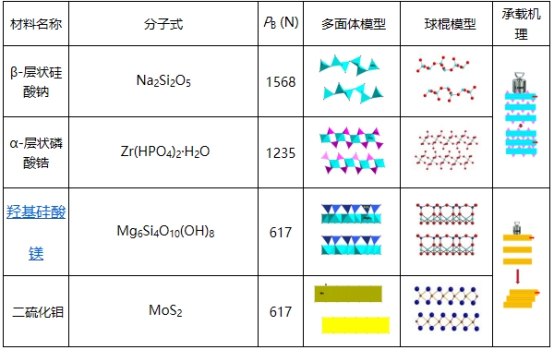

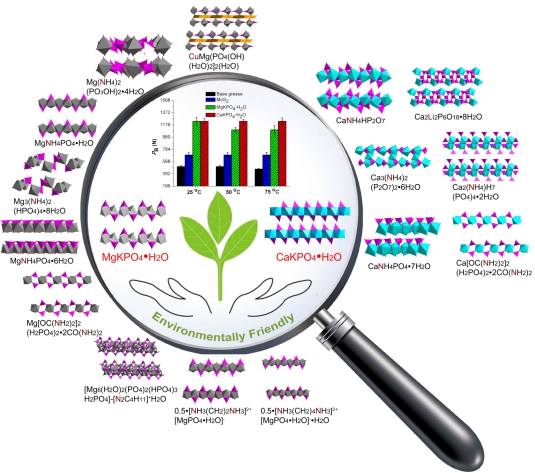

Recently, this group compared the tribological properties of the classical solid lubrication materials under the uniform tribological test conditions, and established the relationship between the crystal structure and the bearing capacity (table 1) . A laminated material having a folded laminate for higher load-carrying capacity. Based on the established structure-activity relationship of solid lubricating materials, the principles of abundant element resources and environmental protection are followed, the layered potassium magnesium phosphate and layered potassium calcium phosphate materials which can be used as a new type of solid lubricant were selected from the crystallographic database. (figure 1). Xiaosheng Zhang, Wenxing Niu, Yingjing Dai, Hong Xu * and Jinxiang Dong * . Scientific Reports 2018,8,16210; invention patent CN201310169803.5, CN107502422A, CN107502423A screened out of the environment-friendly solid lubricating materials (layered potassium magnesium phosphate, layered potassium phosphate calcium) , has potential application prospects in food, textile, marine machinery and so on; The method of rapid screening materials invented in this paper provides guidance for the synthesis and application of various materials with application potential.

表1 多种经典层状固体润滑材料层板晶体结构(球棍模型与多面体模型)展示及承载机理

图1通过晶体数据库检索筛选出环保型层状磷酸钾镁/钙作为固体润滑剂

Copyright COLLEGE OF CHEMICAL ENGINEERING AND TECHNOLOGY, Taiyuan University of Technology

No.79 West Street Yingze,Taiyuan,Shanxi,P.R.China 030024 Tel:+86 0351-6010111